cromox® stainless steel master links and sub-assemblies are used in hoists and as an adaptive solution within LIFTING applications. Together with our comprehensive cromox® LIFTING range, this gives you a perfectly harmonised system solution that impresses with its high load-bearing capacity, corrosion resistance and simple and safe handling.

cromox® stainless steel master links and sub-assemblies are manufactured by machine with the utmost precision.

With their corrosion resistance and high-quality surface, they are ideal for use in clean rooms, the food industry, meat processing, the chemical industry, and the pharmaceutical sector. But the oval rings made of stainless steel also impress with their long-term resistance in offshore applications when used in salt water or in pickling plants in contact with acids. cromox® master links are available in "1-leg" and "2-leg" versions and the cromox® sub-assemblies are available in "3-leg" and "4-leg" versions.

All our master links have something in common:

With the cromox® stainless steel sub-assemblies for chains, we complete our holistic stainless steel product portfolio designed for system solutions.

With our long-standing market presence and internationally recognised expertise in the lifting and industrial sector, Ketten Wälder GmbH has established itself as a reliable partner for master links and sub-assemblies.

The cromox® master links and sub-assemblies are testament to our company's in-depth industry knowledge and extensive experience in lifting and conveyor technology. We offer solutions that not only fulfil the high demands of the industry, but also impress with their reliability and functionality. These products are in line with our commitment to quality, safety, and innovation, which makes our products an indispensable part of efficient system solutions.

The use of corrosion-resistant materials is essential in environments with high corrosion resistance requirements, such as chemical plants, in the maritime or offshore industry or in areas exposed to severe weather conditions. Master links and sub-assemblies made of stainless steel play an important role here, as they ensure the stable and secure suspension of objects.

These components must be made of materials that can withstand these conditions, especially when exposed to high loads, such as chemicals, salt water or high temperatures.

The stainless steel chosen by Ketten Wälder GmbH for the cromox® product line is a material that is particularly suitable for these applications. The alloys with a high chromium and nickel content are particularly noteworthy here. They form a thin but very dense and stable layer of chromium oxide on the surface, which protects the underlying material from corrosion.

When selecting the right material for a sub-assembly or master link, it is important to precisely define the environment and load to which the components will be exposed. This is the only way to ensure safe, reliable, and long-term function.

System solutions in the lifting industry refer to integrated and comprehensive solutions that cover all aspects of lifting operations and are ideally offered by one manufacturer in a coordinated manner. In addition to the lifting equipment itself (such as chains, lifting links and heads, load hooks, connecting links and other lifting points), this can also include the maintenance and repair of these products, training for operators and other services.

The advantage of system solutions ("everything from a single source") is that customers have a single supplier for all their product requirements in relation to lifting operations. Especially when it comes to customised system solutions, it is an advantage to have a single point of contact and manufacturer. The individual components are harmonised with each other. This can improve the efficiency and effectiveness of lifting operations and production processes, reduce the risk of problems or errors, and cut costs.

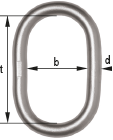

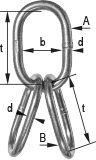

| Type | WLL (t) | For Chain | Dimensions (mm) | Weight (kg, approx.) | ||||

|---|---|---|---|---|---|---|---|---|

| 1-leg | 2-leg | d | t | b | ||||

| CAG 6* | 0,23 | - | - | 6 | 60 | 25 | 0,043 |  |

| CAG 8* | 0,40 | 4 | - | 8 | 54 | 30 | 0,070 | |

| CAG 10 | 0,63 | 5 | 4 | 10 | 80 | 50 | 0,150 | |

| CAG 13 | 1,55 | 6/7/8 | 5/6 | 13 | 110 | 60 | 0,340 | |

| CAG 16 | 2,45 | 10 | 7/8 | 16 | 110 | 60 | 0,530 | |

| CAG 18 | 3,55 | - | 10 | 18 | 135 | 75 | 0,800 | |

| CAG 22 | 6,00 | 13/16 | 13 | 22 | 160 | 90 | 1,500 | |

| CAG 26 | 8,00 | 18 | 16 | 26 | 180 | 100 | 2,300 | |

| CAG 32 | 12,00 | 20 | 18 | 32 | 200 | 110 | 3,900 | |

| CAG 36 | 16,00 | 22 | 20 | 36 | 260 | 140 | 6,350 | |

| CAG 45 | 20,00 | 26 | 22 | 45 | 320 | 175 | 12,000 | |

| CAG 50 | 24,00 | 32 | 26 | 50 | 340 | 190 | 16,000 | |

| CBG 5 | 0,40 | - | - | 5 | 22 | 9 | 0,012 | |

| CBG 6 | 0,63 | - | - | 6 | 26 | 13 | 0,018 | |

| CBG 8 | 1,25 | - | - | 8 | 35 | 19 | 0,046 | |

| CBG 10 | 1,55 | - | - | 10 | 44 | 25 | 0,092 | |

| CBG 13 | 2,45 | - | - | 13 | 54 | 25 | 0,195 | |

| CBG 16 | 3,85 | - | - | 16 | 70 | 34 | 0,370 | |

| CBG 18 | 6,00 | - | - | 18 | 85 | 40 | 0,530 | |

| CBG 22 | 7,60 | - | - | 22 | 115 | 50 | 1,065 | |

| CBG 26 | 9,60 | - | - | 26 | 140 | 65 | 1,825 | |

| CBG 32 | 15,00 | - | - | 32 | 140 | 70 | 2,900 | |

| CBG 36 | 20,00 | - | - | 36 | 160 | 80 | 4,200 | |

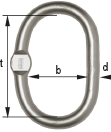

| Type | WLL (t) | For Chain | Dimensions (mm) | Weight (kg, approx.) | ||||

|---|---|---|---|---|---|---|---|---|

| 1-leg | 2-leg | d | t | b | ||||

| CAGF 8 | 0,40 | 4 | - | 8 | 54 | 30 | 0,070 | These master links have a flattened section to allow the use of connectors (e.g. Clevis Shackle type CGS).  |

| CAGF 10 | 0,63 | 5 | 4 | 10 | 80 | 50 | 0,150 | |

| CAGF 13 | 1,55 | 6/7/8 | 5/6 | 13 | 110 | 60 | 0,340 | |

| CAGF 16 | 2,45 | 10 | 7/8 | 16 | 110 | 60 | 0,530 | |

| CAGF 18 | 3,55 | - | 10 | 18 | 135 | 75 | 0,800 | |

| CAGF 22 | 6,00 | 13/16 | 13 | 22 | 160 | 90 | 1,500 | |

| CAGF 26 | 8,00 | 18 | 16 | 26 | 180 | 100 | 2,300 | |

| CAGF 32 | 12,00 | 20 | 18 | 32 | 200 | 110 | 3,900 | |

| CAGF 36 | 16,00 | - | 20 | 36 | 260 | 140 | 6,350 | |

| CBGF 10 | 1,55 | - | - | 10 | 44 | 25 | 0,092 | |

| CBGF 13 | 2,45 | - | - | 13 | 54 | 25 | 0,195 | |

| CBGF 16 | 3,85 | - | - | 16 | 70 | 34 | 0,370 | |

| CBGF 18 | 6,00 | - | - | 18 | 85 | 40 | 0,530 | |

| CBGF 22 | 7,60 | - | - | 22 | 115 | 50 | 1,065 | |

| CBGF 26 | 9,60 | - | - | 26 | 140 | 65 | 1,825 | |

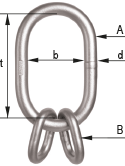

| Type | WLL (t) | For Chain | Dimensions (mm) | Weight (kg, approx.) | ||||

|---|---|---|---|---|---|---|---|---|

| β = 45° | β = 60° | d | t | b | ||||

| CAK 10/8 | 0,80 | 0,60 | 4 | A 10 B 8 | 80 35 | 50 19 | 0,240 |  |

| CAK 13/10 | 1,30 | 0,90 | 5 | A 13 B 10 | 110 44 | 60 25 | 0,520 | |

| CAK 16/13 | 2,65 | 1,85 | 6/7 | A 16 B 13 | 110 54 | 60 25 | 0,970 | |

| CAK 18/16 | 3,25 | 2,30 | 8 | A 18 B 16 | 135 70 | 75 34 | 1,600 | |

| CAK 22/18 | 5,15 | 3,65 | 10 | A 22 B 18 | 160 85 | 90 40 | 2,760 | |

| CAK 26/22 | 8,15 | 5,75 | 13 | A 26 B 22 | 180 115 | 100 50 | 4,450 | |

| CAK 32/26 | 12,60 | 9,00 | 16 | A 32 B 26 | 200 140 | 110 65 | 7,550 | |

| CAK 45/32 | 16,80 | 12,00 | 18 | A 45 B 32 | 320 140 | 175 70 | 17,800 | |

| CAK 50/36 | 23,10 | 16,50 | 22 | A 50 B 36 | 340 160 | 190 80 | 24,400 | |

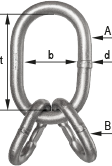

| Type | WLL (t) | For Chain | Dimensions (mm) | Weight (kg, approx.) | ||||

|---|---|---|---|---|---|---|---|---|

| β = 45° | β = 60° | d | t | b | ||||

| CAKF 10/8 | 0,80 | 0,60 | 4 | A 10 B 8 | 80 35 | 50 19 | 0,240 | |

| CAKF 13/10 | 1,30 | 0,90 | 5 | A 13 B 10 | 110 44 | 60 25 | 0,520 | These master links have a flattened section to allow the use of connectors (e.g. Clevis Shackle type CGS).  |

| CAKF 16/13 | 2,65 | 1,85 | 6/7 | A 16 B 13 | 110 54 | 60 25 | 0,970 | |

| CAKF 18/16 | 3,25 | 2,30 | 8 | A 18 B 16 | 135 70 | 75 34 | 1,600 | |

| CAKF 22/18 | 5,15 | 3,65 | 10 | A 22 B 18 | 160 85 | 90 40 | 2,760 | |

| CAKF 26/22 | 8,15 | 5,75 | 13 | A 26 B 22 | 180 115 | 100 50 | 4,450 | |

| CAKF 32/26 | 12,60 | 9,00 | 16 | A 32 B 26 | 200 140 | 110 65 | 7,550 | |

| CAKF 45/32 | 16,80 | 12,00 | 18 | A 45 B 32 | 320 140 | 175 70 | 17,800 | |

| Type | WLL (t) | Dimensions (mm) | Weight (kg, approx.) | ||||

|---|---|---|---|---|---|---|---|

| β = 45° | β = 60° | d | t | b | |||

| CAKS 16/13 | 1,80 | 1,25 | A 16

B 13 | 110 110 | 60 60 | 1,210 |  |

| CAKS 16/16 | 2,40 | 1,70 | A 16 B 16 | 110 110 | 60 60 | 1,590 | |

| CAKS 18/16 | 3,25 | 2,25 | A 18 B 16 | 135 110 | 75 60 | 1,860 | |

| CAKS 22/18 | 5,00 | 3,50 | A 22 B 18 | 160 135 | 90 75 | 3,100 | |

| CAKS 26/22 | 8,50 | 5,95 | A 26 B 22 | 180 160 | 100 90 | 5,300 | |

| CAKS 32/26 | 10,75 | 7,50 | A 32 B 26 | 200 180 | 110 100 | 8,500 | |

| CAKS 36/32 | 13,60 | 9,50 | A 36 B 32 | 260 200 | 140 110 | 14,150 | |

Master links are used to hang objects securely and stably. They can be used in many ways, for example in technology, construction or in various industries (e.g. in clean rooms, in the food industry or in the maritime industry).;

There are several standards and regulations concerning master links and sub-assemblies. General requirements for the design, testing and labelling of master links and heads or specific requirements and test methods for the design and manufacture of master links and heads are defined here.

Important: Not all master links and heads must comply with the same standards. It is important to always consider the specific requirements and standards for the respective application when selecting master links and heads.

cromox® stainless steel master links and heads are manufactured to the highest precision and quality from 1.4462 Duplex / AISI 318LN stainless steel. They correspond to Grade 60 and offer maximum load-bearing capacity and safety in every respect.

Master links and sub-assemblies made of stainless steel are particularly durable and can therefore be used in environments with high corrosion resistance requirements, such as in chemical plants, in the maritime or offshore industry or in areas exposed to severe weather conditions. They can also withstand particularly high temperatures and retain their stability and function over a long period of time.

Made of high-quality stainless steel, the cromox® master links and heads keep your objects secure and stable. In combination with the comprehensive cromox® LIFTING programme, you can rely on a high-performance and durable system solution.