Shorteners (cromox® CVE) and sub-assemblies with shortener (cromox® CVK) allow the chain length or the length of a chain suspension to be adjusted quickly and easily on site – with millimetre precision. With little effort, the length of the chain slings can be adjusted with a chain shortener exactly as required for the respective application. The cromox® shorteners and sub-assemblies with shortener are made of stainless steel. This special steel is also called inox steel (from the French "inoxydable", meaning "non-corroding" or "rust-free"). The shortening hooks from Ketten Wälder GmbH have special durability and functional design. Naturally, the entire combination of shortener, chain slings and load-bearing chain links is tested for fatigue strength in our own Lloyd's Register-certified test laboratory as standard.

Our sub-assemblies with shortener CVK are characterised by their customised design for demanding lifting tasks, with a focus on quality and safety. Our products offer an efficient and flexible solution for a wide range of applications – made possible by Ketten Wälder GmbH's many years of expertise and innovation.

At Ketten Wälder GmbH, we attach great importance to the quality of our products, including our shorteners, which are made from high-quality materials to ensure durability and maximum performance under all operating conditions. The cromox® shorteners are known for their robustness and reliability, making them a preferred choice in the lifting industry.

The special design of the cromox® chain shortener makes it particularly safe and flexible to use. Incorrect use is therefore impossible, and the chain suspensions can be quickly adjusted to the correct length. Made from stainless steel, the products are corrosion-resistant and particularly durable.

All benefits at a glance:

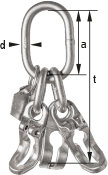

| Type | WLL (t) | Dimensions (mm) | Weight (kg, approx.) | |||

|---|---|---|---|---|---|---|

| d | t | a | ||||

| CVE 04 | 0,40 | 17 | 74 | 32 | 0,170 |  |

| CVE 05 | 0,63 | 24 | 93 | 40 | 0,280 | |

| CVE 06 | 0,90 | 25 | 112 | 45 | 0,455 | |

| CVE 07 | 1,25 | 27 | 131 | 53 | 0,750 | |

| CVE 08 | 1,55 | 28 | 148 | 56 | 1,000 | |

| CVE 10 | 2,45 | 38 | 187 | 70 | 2,000 | |

| CVE 13 | 3,85 | 48 | 243 | 91 | 4,500 | |

| CVE 16 | 6,00 | 56 | 299 | 108 | 7,600 | |

| CVE 18 | 8,00 | 67 | 336 | 122 | 9,500 | |

The cromox® stainless steel sub-assemblies with shortener are available in 1 – leg to 4 – leg options. They have a load capacity of up to 16.8 tonnes (4-leg) and are tested for fatigue strength in the combination of shortener, chain slings and load-bearing chain link.

All our sub-assemblies with shortener have this in common:

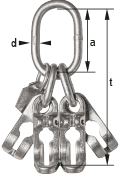

| Type | WLL (t) | Dimensions (mm) | Weight (kg, approx.) | |||

|---|---|---|---|---|---|---|

| d | t | a | ||||

| CVK 1 – 4 | 0,40 | 8 | 128 | 54 | 0,36 | |

| CVK 1 – 5 | 0,63 | 10 | 173 | 80 | 0,55 |  |

| CVK 1 – 6 | 0,90 | 13 | 222 | 110 | 0,96 | |

| CVK 1 – 7 | 1,25 | 13 | 241 | 110 | 1,20 | |

| CVK 1 – 8 | 1,55 | 13 | 258 | 110 | 1,50 | |

| CVK 1 – 10 | 2,45 | 16 | 297 | 110 | 2,70 | |

| CVK 1 – 13 | 3,85 | 22 | 403 | 160 | 6,17 | |

| CVK 1 – 16 | 6,00 | 22 | 459 | 160 | 9,27 | |

| CVK 1 – 18 | 8,00 | 26 | 516 | 180 | 11,92 | |

| Type | WLL (t) | Dimensions (mm) | Weight (kg, approx.) | ||||

|---|---|---|---|---|---|---|---|

|  | d | t | a | |||

| CVK 2 – 4 | 0,55 | 0,40 | 10 | 154 | 80 | 0,53 | |

| CVK 2 – 5 | 0,85 | 0,63 | 13 | 203 | 110 | 1,09 |  |

| CVK 2 – 6 | 1,25 | 0,90 | 13 | 222 | 110 | 1,42 | |

| CVK 2 – 7 | 1,75 | 1,25 | 16 | 241 | 110 | 2,20 | |

| CVK 2 – 8 | 2,15 | 1,55 | 16 | 258 | 110 | 2,70 | |

| CVK 2 – 10 | 3,45 | 2,45 | 18 | 322 | 135 | 4,97 | |

| CVK 2 – 13 | 5,40 | 3,85 | 22 | 403 | 160 | 10,67 | |

| CVK 2 – 16 | 8,40 | 6,00 | 26 | 479 | 180 | 17,67 | |

| CVK 2 – 18 | 11,20 | 8,00 | 32 | 536 | 200 | 23,02 | |

| Type | WLL (t) | Dimensions (mm) | Weight (kg, approx.) | ||||

|---|---|---|---|---|---|---|---|

|  | d | t | a | |||

| CVK 3 – 4 | 0,80 | 0,60 | 10/8 | 189 | 80 | 0,87 | |

| CVK 3 – 5 | 1,30 | 0,90 | 13/10 | 247 | 110 | 1,59 |  |

| CVK 3 – 6 | 1,90 | 1,35 | 16/13 | 276 | 110 | 2,50 | |

| CVK 3 – 7 | 2,65 | 1,85 | 16/13 | 295 | 110 | 3,39 | |

| CVK 3 – 8 | 3,25 | 2,30 | 18/16 | 353 | 135 | 4,77 | |

| CVK 3 – 10 | 5,15 | 3,65 | 22/18 | 432 | 160 | 8,93 | |

| CVK 3 – 13 | 8,15 | 5,75 | 26/22 | 538 | 180 | 18,12 | |

| CVK 3 – 16 | 12,60 | 9,00 | 32/26 | 639 | 200 | 30,52 | |

| CVK 3 – 18 | 16,80 | 12,00 | 45/32 | 796 | 320 | 46,42 | |

| Type | WLL (t) | Dimensions (mm) | Weight (kg, approx.) | ||||

|---|---|---|---|---|---|---|---|

|  | d | t | a | |||

| CVK 4 – 4 | 0,80 | 0,60 | 10/8 | 189 | 80 | 1,04 | |

| CVK 4 – 5 | 1,30 | 0,90 | 13/10 | 247 | 110 | 1,87 |  |

| CVK 4 – 6 | 1,90 | 1,35 | 16/13 | 276 | 110 | 2,96 | |

| CVK 4 – 7 | 2,65 | 1,85 | 16/13 | 295 | 110 | 4,14 | |

| CVK 4 – 8 | 3,25 | 2,30 | 18/16 | 353 | 135 | 5,77 | |

| CVK 4 – 10 | 5,15 | 3,65 | 22/18 | 432 | 160 | 10,93 | |

| CVK 4 – 13 | 8,15 | 5,75 | 26/22 | 538 | 180 | 22,62 | |

| CVK 4 – 16 | 12,60 | 9,00 | 32/26 | 639 | 200 | 38,12 | |

| CVK 4 – 18 | 16,80 | 12,00 | 45/32 | 796 | 320 | 55,92 | |

Fatigue strength refers to the ability of a material to withstand repeated or continuous stress without fatigue or failure. As part of quality control, it is essential to test and verify the fatigue strength of the combination of shortener, chain, and load-bearing chain link.

Fatigue strength testing is carried out in our in-house Lloyd's Register certified test laboratory, where the component is subjected to repeated loading and unloading under controlled conditions to determine its ability to withstand fatigue and failure.

This involves measuring both the maximum load and the number of cycles the component can withstand before it fails. It is particularly important to test the fatigue strength of the combination of shortener, chain, and load-bearing chain link, as these components are often exposed to high and regular loads. Failure of these components can have serious consequences, especially in safety-critical applications.

In almost all industrial applications, it is essential to avoid misuse to ensure the safety and efficiency of the work process. The development of a chain shortener is no different. Here are some aspects that have been considered in the cromox® shortener to minimise the risk of misuse through special design:

Shorteners in chain slings refer to components that are used to adjust the length of a chain sling. They are an important component in lifting technology to lift, move or secure loads safely and efficiently. A common shortening method is the chain shortener or shortening hook.

Shorteners for slings and chain suspensions are used in various industries, including construction, logistics, mechanical engineering, and heavy industry. They are used to safely lift, move, or secure loads. They can be attached to cranes, hoists, or other equipment. It is important that the shortenings for slings are properly maintained and used to ensure safety.

Shorteners and sub-assemblies with shorteners for chain slings differ mainly in their design and application. A shortening is a single element that is used to adjust the length of a chain sling. A sub-assembly with shortener, on the other hand, is a combination of several shorteners that are used together to shorten chain slings (1-leg to 4-leg) to a certain length. The choice between shortening and sub-assemblies with shortener depends on the specific application and the user's requirements.

Shorteners made of stainless steel are highly resistant to corrosion, which basically extends their service life and reduces their maintenance.

Stainless steel shorteners for chain slings offer several advantages. Firstly, they improve the overall strength and durability of the chain as they distribute the pressure over several links instead of concentrating it on a single link. Secondly, shortening enables more flexible handling and adaptation of the chain to different load sizes and shapes. Thirdly, they increase safety as they prevent the load from slipping or coming loose.

The functional design and high load-bearing capacity make the cromox® shorteners made of stainless steel (inox) an indispensable tool for individually shortening chain suspensions for different applications - for greater efficiency and safety in your work processes.