The 360° rotation lifting points allows the lifting point to align itself in the direction of pull during the lifting process. This achieves maximum flexibility. Swivel lifting points are therefore often used in multi-strand solutions, but also in many other applications where this kind of flexibility is required.

A double joint makes our cromox® lifting point rotate 360° rotatable, enabling ideal alignment with the chain sling. Twisting or knotting of load-bearing chains is prevented, thus increasing the efficiency of the work process. The high fatigue strength and load capacity of the swivel lifting points, as well as the 4-fold safety in all load directions, further enhance the practicality and the reliable and consistent quality of the product.

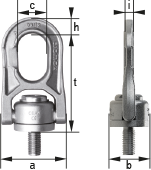

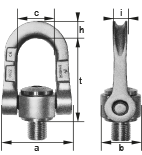

| Type | WLL (t) | Dimensions (mm) | Thread | Thread length* | Weight (kg, approx.) |  | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a | b | c | h | i | t | |||||||

| CDAW 05 | 0,50 | 66 | 42 | 31,0 | 16,5 | 11,0 | 100 | M 10 | 15 | 0,500 | ||

| CDAW 1 | 1,00 | 66 | 42 | 31,0 | 16,5 | 11,0 | 100 | M 14 | 20 | 0,500 | ||

| CDAW 2 | 2,00 | 100 | 50 | 53,5 | 26,0 | 20,5 | 127 | M 20 | 30 | 1,770 |  | |

| CDAW 3 | 3,00 | 100 | 50 | 53,5 | 26,0 | 20,5 | 127 | M 27 | 40 | 1,840 | ||

| CDAW 5 | 5,00 | 120 | 60 | 64,0 | 31,5 | 26,0 | 146 | M 36 | 54 | 3,500 | ||

| CDAW 8 | 8,00 | 150 | 85 | 80,5 | 38,5 | 30,0 | 180 | M 42 | 62 | 6,550 | ||

| CDAW 10 | 10,00 | 171 | 98 | 92,5 | 44,0 | 35,0 | 207 | M 48 | 72 | 9,620 | ||

The positive properties of stainless steel, such as strength, durability, corrosion resistance, and temperature resistance, are of great importance for high-quality swivel lifting points. Stainless steel swivel lifting points are mainly used in industry and shipping. They serve to hold loads securely while allowing a 360° rotation and thus maximum flexibility with high and reliable load capacity.

The resistance of stainless steel to the damaging effects of salt, water, and other corrosive substances makes this material ideal for use in harsh environmental conditions. Even under extreme heat and cold conditions, corrosion-resistant stainless steel never loses its strength and performance, which is crucial for load capacity among other things.

A 360° rotatable swivel lifting point is a special product within the portfolio of lifting equipment. It can rotate and swivel in any direction, thereby enabling maximum flexibility, safety, and efficiency when lifting and moving loads. In addition, the 360° rotation minimizes the risk of lateral forces, which can occur when lifting loads. This lifting equipment can be used for a wide variety of applications, from the construction industry to logistics and shipping.

It is particularly important that a 360° rotatable swivel lifting point meets the corresponding safety standards, has a sufficient load capacity for the intended load, and is thoroughly tested. The in-house testing laboratory of Ketten Wälder GmbH, certified by Lloyd's Register, tests cromox® products up to 160 tons.

A swivel lifting point is a mechanical attachment device used in lifting technology. It consists of a swivel part that can rotate 360° and an attachment point for securing a load. The mobility allows the load to be rotated or swiveled during the lifting process without twisting or adding additional load to the supporting chains.

Swivel lifting points are used wherever loads need to be lifted and/or rotated, transported, and positioned. They are commonly found in industry, construction, logistics, and many other areas where heavy loads need to be moved. They are an essential part of cranes, hoists, and other lifting devices.

The load capacity of a swivel lifting point refers to the maximum weight the swivel lifting point can safely carry or hold. This is a value that must not be exceeded to ensure safety during lifting operations. The load capacity of a specific swivel lifting point can vary depending on various factors, such as the material the swivel is made of, its size and shape, and last but not least its construction. They can carry loads from a few hundred kilograms to several tons.

The swivel lifting points from cromox® have a load capacity of up to 10 tons. Generally, the load capacity increases with the rise in construction dimensions, thread length, and weight. The individual load capacities can be seen in the product table. The last numbers in the product designation indicate the load capacity. For example, the swivel lifting point CDAW-05 has a load capacity of 0.5 tons, the product CDAW-5 has a load capacity of 5 tons.

It is important that you observe the specific manufacturer's specifications to ensure that the swivel lifting point is suitable for the load you want to lift.

The cromox® products are manufactured by Ketten Wälder GmbH on over 5,500 m² of production space in Bad Endorf, Upper Bavaria, and distributed in over 50 countries worldwide. An in-house test laboratory certified by Lloyd's Register tests the products up to 160 tons.

For over 75 years, the 100% owner-managed company has been working every day to make their customers' requirements their own goals. Striving for perfection is as much a part of its goals as quality and agility. With a combination of excellence and progress, Ketten Wälder shapes the market decisively with high-quality products "Made in Germany".

The grade of swivel lifting points refers to the load-bearing capacity of these components. It is a classification that determines what load a swivel lifting point can safely withstand.

This classification also contains information about the material quality of the product. There are different standards for swivel lifting points, depending on the industry and region.

It is important that users know the industry-specific requirements to ensure that they select the right components for their application.